Without machines, you can’t run a business making furniture, simple as that. Yes, a lot of the finishing work for furniture requires the touch, feel and judgement of a human hand, as does the pure work of making smaller objects that require carving and sanding. Most larger commissions such as kitchens and shelving units, wardrobes and so on all require the fast, accurate sawing and thicknessing of very large sheets of timber of MDF, and that’s where machines save time. Here at Mark Williamson Furniture, we are always looking at improving and upgrading the woodworking machinery that we have, and it certainly doesn’t come cheap – but to make the best furniture possible, you need the best machinery to do it.

We recently upgraded some of our machines. We invested in a spindle moulder (fifth photo down) – this is a brand new machine, replacing an old machine that had sadly seen better days! Built to Mark’s specifications in the factory in Belgium, its purpose is for machining grooves, profiles and rebates into timber and shaping curved components. After piecing it together on delivery and experiencing a few teething problems, it is all up and running.

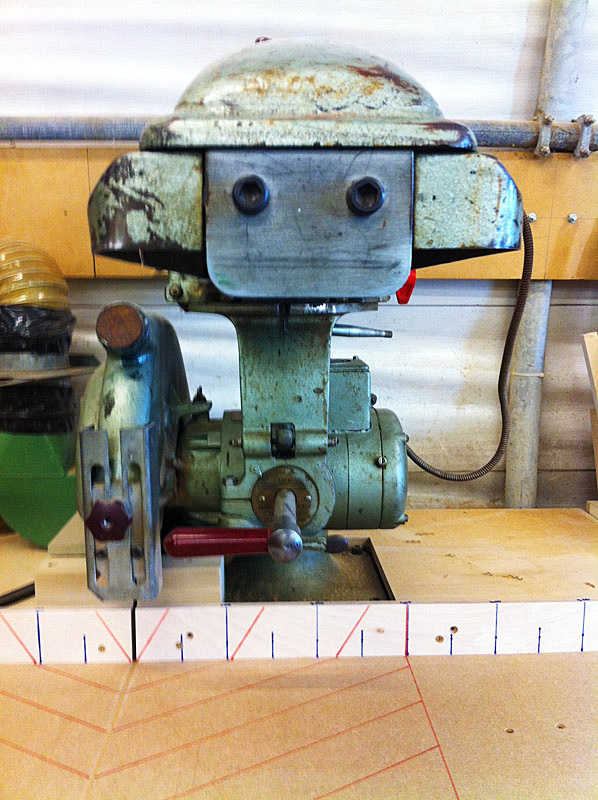

We also brought in a new traditional British-made Wadkin crosscut saw – not brand new but new to us! This is for crosscutting timber to length. It also replaces an old machine mostly for health and safety reasons – this one has the required stops and safety features to meet regulations.

And finally we also bought a tenoner- again not brand new, but new to us. It is a dedicated machine for cutting tenons for mortice and tenon joints. This machine doesn’t replace an existing machine so will increase our productivity as it has a dedicated purpose.

If you would like us to build some beautiful bespoke furniture built in Bucks for you and your home, please contact us here for a chat.