Ok, maybe not workshop secrets exactly, but a glimpse into how we work. In our last blog post, we published some very kind words from some clients about the two tables that we designed and built for them – you can see photography of the finished tables in that post.

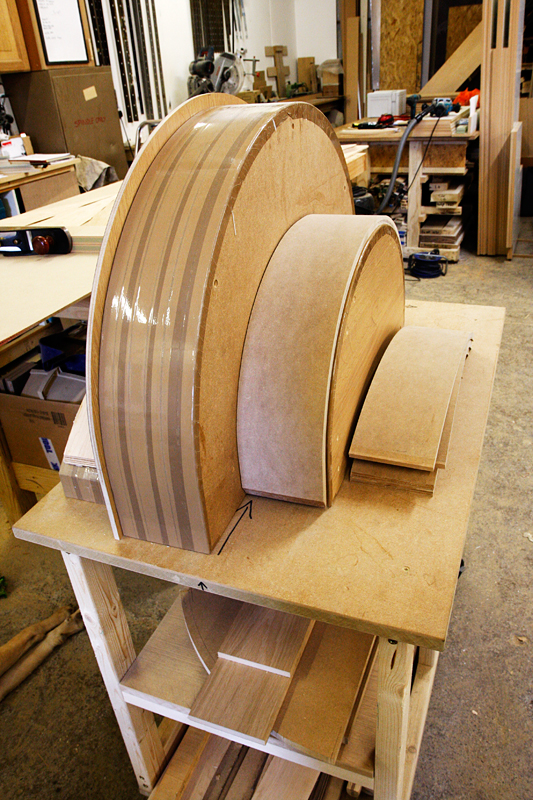

The photos that we have posted here above give you an idea the hours and hours of work and attention to detail that it requires to construct fine tables like these. In this case, the design started from an idea discussed between Mark and the clients, and the idea became a sketch in Mark’s capable hands. Because these tables were so particularly individual and required more of a design or artistic led approach, rather than using a precise but unforgiving compter design programme. Once agreed by the clients, work went ahead, and you can see that it is a process of very carefully working with separate parts and materials – veneers, hand-carved legs, walnut stringing details, curved drawer sections and so on. The results, as you can see in the previous blog post, we think are stunning – as do the clients. Want something similar for your home? Contact us here for a chat.

For those of you more interested in the technical side of how built these tables, here is the complete spec:

– Set of two, half elliptical, free-standing side tables – one to be 800mm high x 910mm wide at widest point x 420 deep at deepest point – the other to be 800mm high x 600mm wide at widest point x 250mm deep at deepest point.

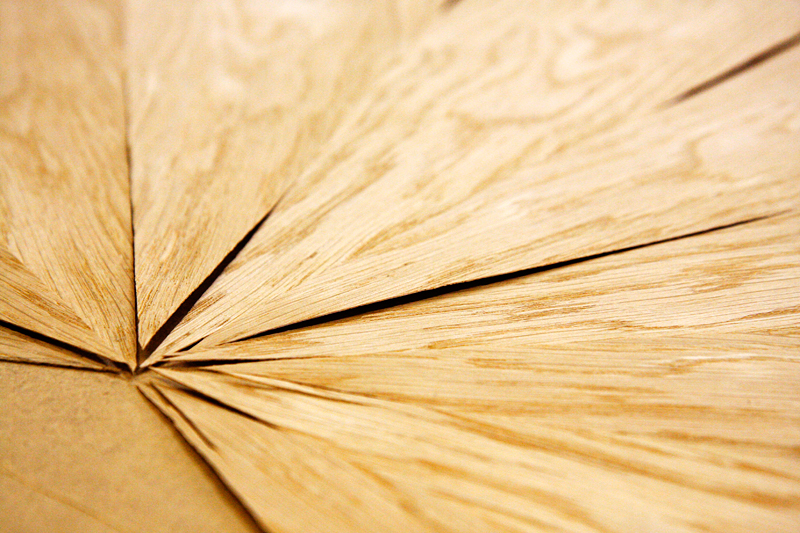

– Each table to have four legs, a bottom shelf and a top with frieze rail. Top, shelf and frieze rail to be made from MDF with book matched, European oak veneer in a fan pattern – with grain continuing from the top, down the frieze rail.

– Edges of top and shelf to have a fine, walnut stringing detail.

– Large table to have one central drawer in the frieze rail , drawer to be constructed using hand dovetailed maple, with drawer slips and solid floating bottom– designed to fit in seamlessly with frieze rail, with a small, bowed, walnut handle

– Legs to be solid oak, with a solid piece of walnut running through the middle of each. All legs curved at the back and bible-backed at the front. Legs cut through the top of the table, finished flush to the surface. Legs to flare out and taper to the floor beneath bottom shelf.

– Both tables to be finished using high quality, hard-wearing clear lacquer.

– Both tables to be fixed to wall with concealed fixing to prevent them from becoming unbalanced.